Strength Development in Fiber Enhanced Shells with and Without Polymer as a Function of Dry Time

Fiber enhanced slurries are successful in building shells with fewer dips because thicker individual dip layers are applied. Because of this, drying of these shells could be …

The Choice Between Aluminum Silicates and Fused Silica for Stucco

The use of Aluminum Silicate stucco as a replacement for Fused Silica stucco is investigated. Two different types of backup slurries and three different stuccoes were …

The Importance of Green MOR for Autoclave Cracking

During production trials using a new slurry system containing nylon fiber, a seemingly anomalous observation was made. While clearly lower in Green MOR than the …

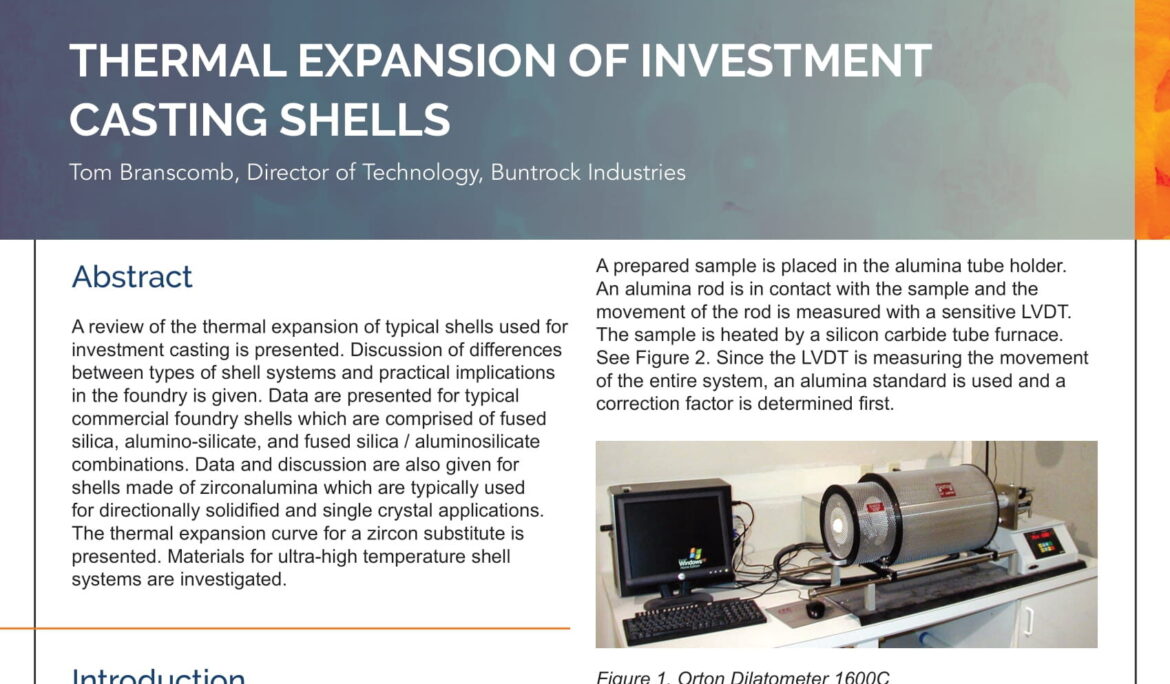

Thermal Expansion of Investment Casting Shells

A review of the thermal expansion of typical shells used for investment casting is presented. Discussion of differences between types of shell systems and practical implications …

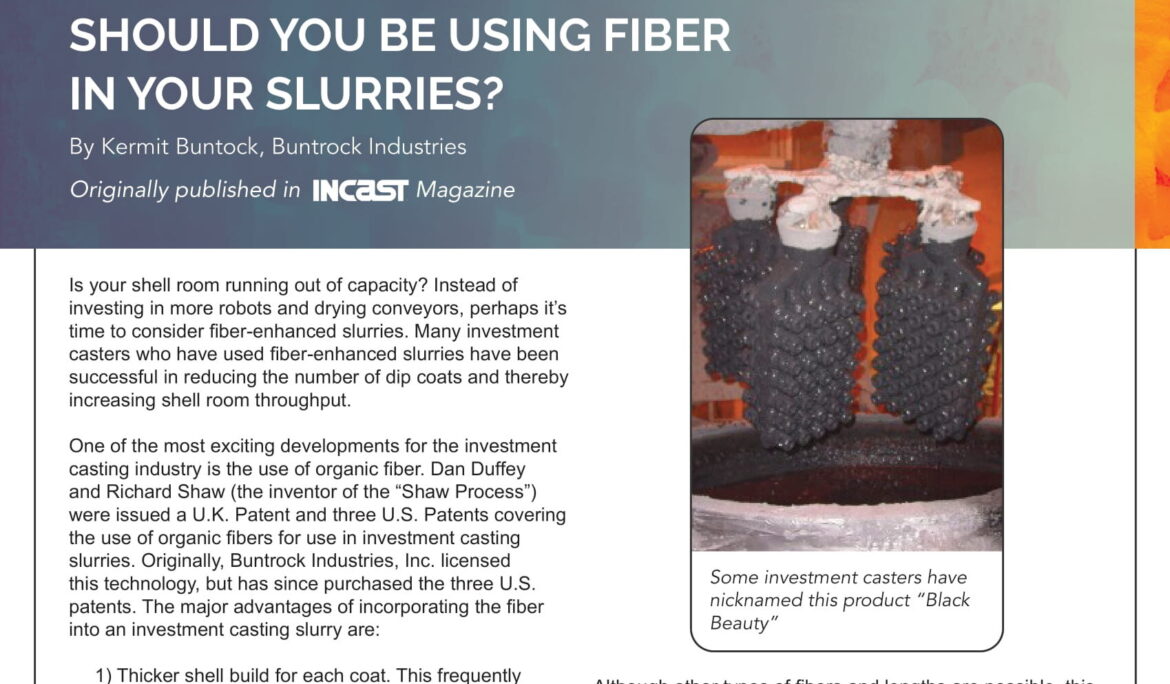

Should You Be Using Fiber in Your Slurries?

Is your shell room running out of capacity? Instead of investing in more robots and drying conveyors, perhaps it’s time to …

Key Factors for Shell Making Success

There are many aspects to ensuring success in the shell room: Materials, Equipment, Procedures, Training, and Management. One of the most important aspects is …

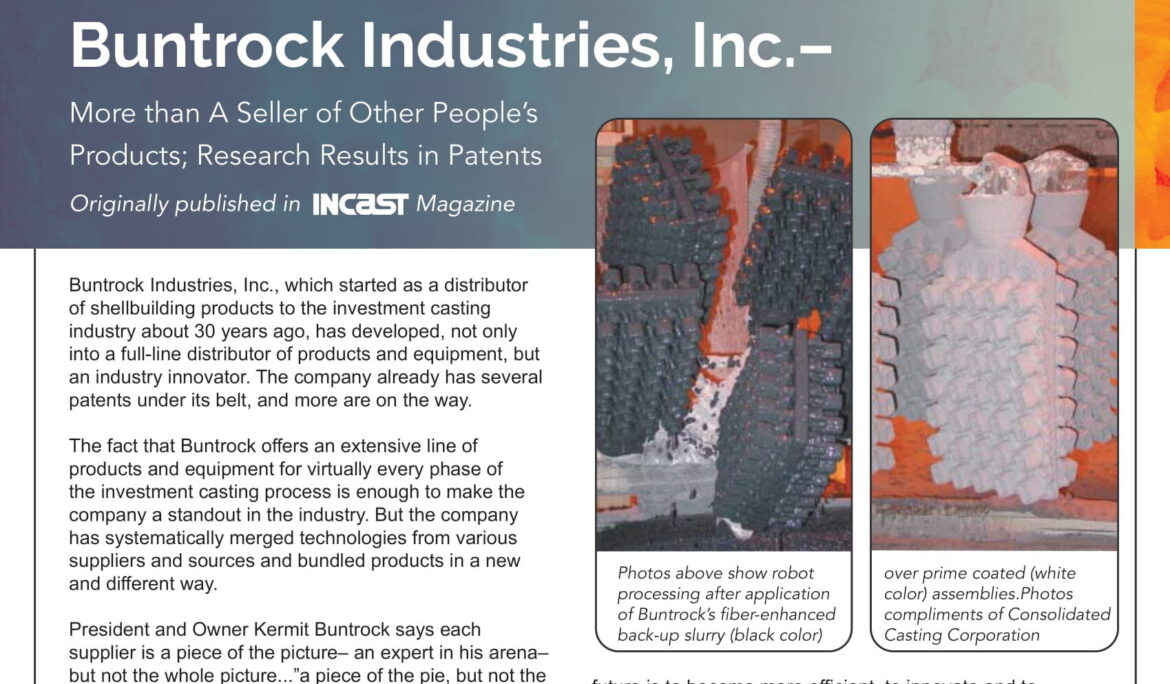

Buntrock Industries Profile in InCast Magazine

Buntrock Industries, Inc., which started as a distributor of shellbuilding products to the investment casting industry about 30 years ago, has developed, not only …

Automatic Process Control of Investment Casting

It is easy to describe automatic process control of investment casting. Charge the furnace, heat the charge uniformly to the desired temperature, then cast. The …